The Physics of Snow Accumulation

Snow is a live load that undergoes constant crystalline transformations. In Toronto's high-rise corridors, the Venturi effect accelerates wind speeds between buildings, creating uneven snow drifts that result in dangerous eccentric loading on scaffold towers.

Density Dynamics

Moisture picking up from Lake Ontario often results in heavy, wet snow. A single 30 cm accumulation can range from 15 kg/m² for dry powder to over 100 kg/m² for wet snow, which can reach a platform's maximum intended load before any labour or equipment is added.

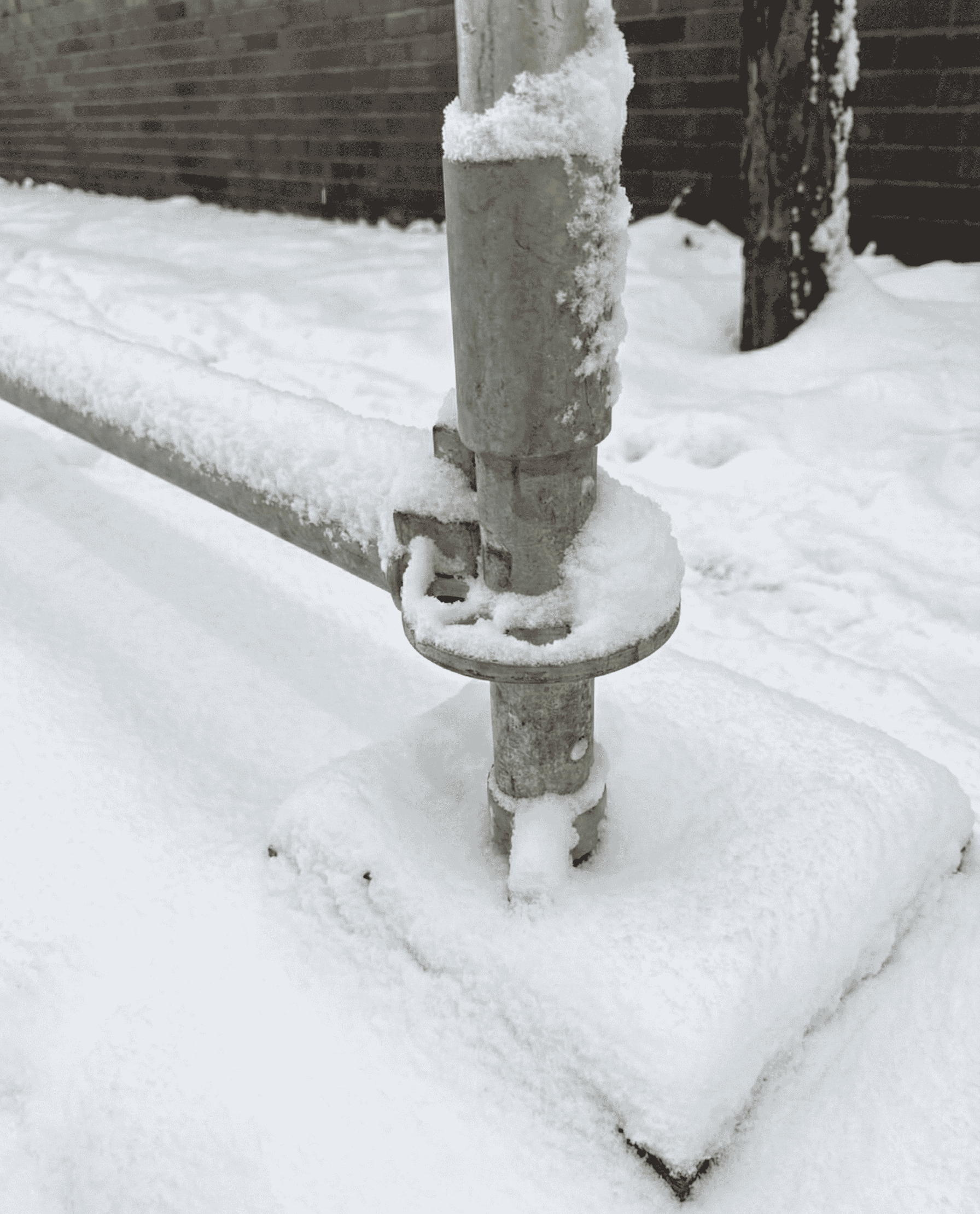

Flash Freezing and Consolidation

The proximity to the waterfront creates a microclimate where steel decks flash freeze rapidly. As temperatures fluctuate, melting snow trickles through the pack and refreezes, creating a dense bond to the steel surface that adds significant undetected weight.

| Type of Accumulation | Approx. Density (kg/m³) | Structural Impact |

|---|---|---|

| Freshly Fallen Dry Snow | ~60 kg/m³ | High surface area, low immediate weight. |

| Wind-Packed & Drifting | ~375 kg/m³ | Creates dangerous eccentric loading on towers. |

| Wet Slush & Heavy Ice | ~750 kg/m³ | Critical risk for light-duty access systems. |

| Solid Crystalline Ice | ~915 kg/m³ | Severe load and extreme slip hazard. |